This post is one in a series of feature stories on trends shaping advanced energy markets in the U.S. and around the world, drawn from Advanced Energy Now 2015 Market Report, which was prepared for AEE by Navigant Research.

Combined heat and power (CHP), also known as cogeneration, simultaneously generates electricity and useful heat in an integrated system. This application of technology achieves greater levels of overall efficiency than separate heat and power systems because heat that is wasted in conventional electric generating systems is recovered and put to use. CHP systems can reach thermal efficiencies up to 85%. CHP provides highly efficient electricity and process heat to many industries in the United States; 83 GW of CHP capacity are installed in the United States, which is approximately 8 percent of the national electricity generation capacity and 12 percent of annual power generation. Navigant Research estimates the vast majority of CHP is used for industrial applications, 80% to 90% of the total.

CHP is a type of distributed generation, which is located at or near the point of consumption. It can be deployed quickly, cost effectively, and with few geographic technical limitations. New turbines for CHP systems are typically most cost-effective down to 500 kW and new reciprocating engines down to 50 kW, which significantly increases the number of sites where CHP can be installed. CHP can use both fossil and renewable fuels, such as biogas, waste, and biomass. Natural gas remains the most common fuel source in the United States, at 69%.

There is currently significant policy support for CHP systems in the United States. In a 2012 executive order, President Obama called for 40 GW of new, cost-effective industrial CHP by the end of 2020, which would increase installed capacity by approximately 50%. The U.S. Department of Energy has provided technical assistance on CHP to U.S. commercial and industrial businesses since 2007, through its Regional Clean Energy Application Centers. The next generation of this effort is regional Combined Heat and Power Technical Assistance Partnerships. The CHP Technical Assistance Partnerships will focus on market opportunity analyses, education and outreach, and technical assistance for individual facilities. The partnerships will be supported with $11 million over four years.

The global market for CHP systems in 2014 is estimated at $28.5 billion in 2014, with the United States representing 11% of that total. Recent additions of CHP capacity have been concentrated in New York, California, Texas, and Connecticut. But Industrial CHP has significant room to grow, with the chemicals, pulp and paper, and food manufacturing industries representing some of the biggest opportunities. The American Council for an Energy-Efficient Economy (ACEEE) estimates that 130 GW of CHP potential can still be found in all types of existing facilities – and less than 1% of this technical potential has been installed annually in recent years.

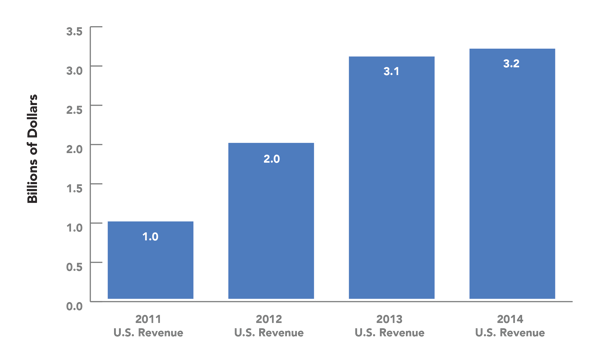

Industrial CHP Revenue

Some emerging CHP technologies are in development, as presented in 2014 at the U.S. DOE Advanced Manufacturing Office Peer Review. A combined heat, hydrogen, and power, or tri-generation (CHHP), system is in testing at an industrial site. Also, an advanced gas turbine-based, ultra-low NOx CHP system is under development, which is expected to achieve 84% system efficiency and meet California Air Resource Board emissions criteria.

Some emerging CHP technologies are in development, as presented in 2014 at the U.S. DOE Advanced Manufacturing Office Peer Review. A combined heat, hydrogen, and power, or tri-generation (CHHP), system is in testing at an industrial site. Also, an advanced gas turbine-based, ultra-low NOx CHP system is under development, which is expected to achieve 84% system efficiency and meet California Air Resource Board emissions criteria.

Recent interest in CHP is driven in part by low natural gas prices and the need for industrial facilities to replace aging boilers to comply with new pollution standards or lower maintenance costs. As a growing number of industrial companies look for cost-effective options to reduce energy costs, CHP in particular represents a promising near-term opportunity utilizing a well-established technology.